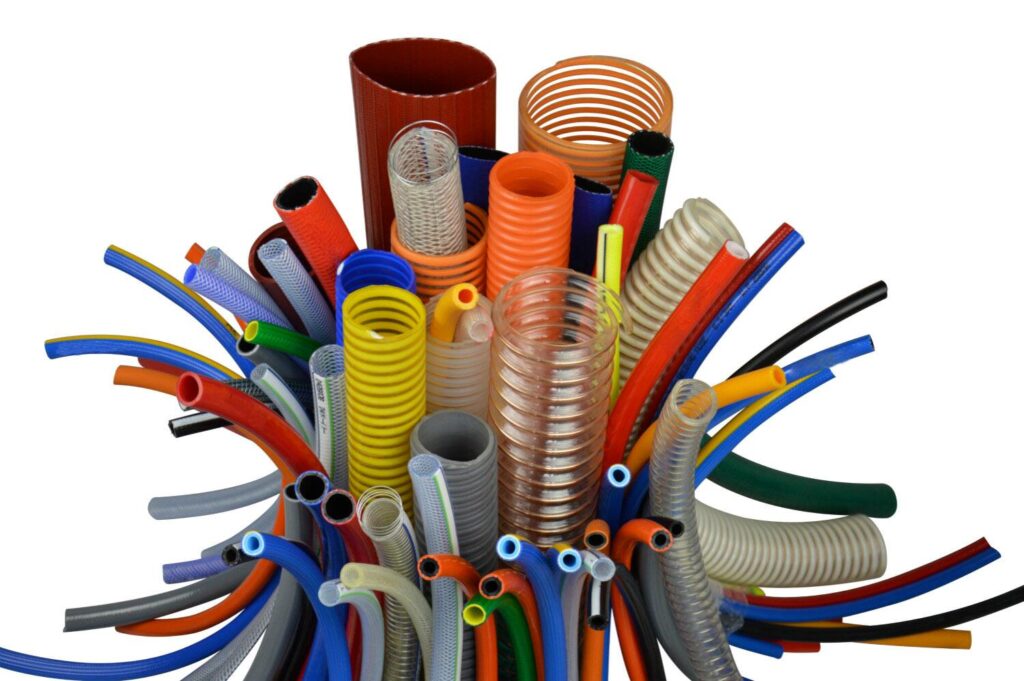

PVC hoses have long been recognized for their durability, flexibility, and wide-ranging applications across industries such as agriculture, construction, and food processing. However, as industrial needs evolve and become more specialized, so does the demand for PVC HOSE Manufacturer that can meet higher standards of performance, safety, and sustainability. Manufacturers are responding to these modern challenges by embracing cutting-edge innovations in materials, production processes, and design. In this article, we explore how PVC hose manufacturers are stepping up to meet the increasing demands of modern industries.

1. Advancing Material Composition

At the heart of PVC hose innovation lies the development of new material compositions. Manufacturers are moving beyond traditional PVC formulations by introducing advanced plasticizers, stabilizers, and other additives that enhance the hose’s flexibility, strength, and resistance to chemicals or extreme temperatures.

For example, manufacturers are now using phthalate-free plasticizers, which are safer for the environment and human health, particularly in applications where hoses come in contact with food or potable water. This shift towards eco-friendly materials is a response to both regulatory pressures and consumer demands for greener products.

Additionally, some manufacturers are experimenting with blending PVC with other polymers, such as polyurethane, to create hybrid hoses. These blends offer improved durability, abrasion resistance, and a wider operating temperature range, making them ideal for industries like construction and mining, where hoses must withstand rough conditions.

2. Reinforcement Technology: Strength Meets Flexibility

While standard PVC hoses are strong, reinforced PVC hoses are setting new standards for strength and durability. By incorporating advanced reinforcement techniques, manufacturers can create hoses that are capable of handling higher pressures and greater mechanical stress without sacrificing flexibility.

One key area of innovation is in the use of spiral-wound steel wire or high-tensile synthetic fibers, which are embedded within the PVC structure. These reinforced hoses are particularly useful in demanding applications like hydraulic systems, where high-pressure fluid transfer is common. The combination of reinforcement materials and PVC’s natural flexibility results in hoses that can maintain structural integrity under extreme conditions, while still being easy to maneuver.

In industries like agriculture and food processing, the ability to offer transparent or semi-transparent reinforced hoses allows for visual inspection of fluid flow, ensuring safety and quality control.

3. Antimicrobial and Anti-Static Solutions

The rise of hygiene-sensitive industries, such as pharmaceuticals and food processing, has led to the development of PVC hoses with antimicrobial properties. These hoses are embedded with additives that prevent the growth of bacteria, mold, and other pathogens, ensuring that industries maintain strict sanitation standards.

This innovation is particularly important in environments where contamination can have serious consequences, such as in the production of medicines or beverages. Antimicrobial PVC hoses help to reduce the risk of cross-contamination and are designed to meet the stringent requirements of global health and safety standards.

Similarly, anti-static PVC hoses are gaining traction in industries where the buildup of static electricity could pose a risk, such as in chemical processing or environments dealing with flammable substances. Anti-static technology integrated into the hose material helps to dissipate static charges, improving safety and preventing dangerous electrical discharges.

4. Lightweight and Flexible Designs for Easy Handling

One of the ongoing challenges in industrial environments is balancing strength with ease of use. While durability is crucial, hoses that are too rigid or heavy can be difficult to install, handle, or adjust. In response, manufacturers are developing lighter, more flexible PVC hoses without compromising on performance.

These lightweight designs are particularly beneficial in industries where mobility is essential, such as in agriculture, where hoses may need to be frequently moved, or in construction, where ease of handling can reduce installation times and labor costs. Additionally, lighter hoses mean reduced transportation costs, which is an added benefit for industries looking to improve operational efficiency.

5. Customization for Industry-Specific Needs

Modern industries require hoses that meet specific needs, and customization has become a key trend in PVC hose manufacturing. From unique dimensions and pressure ratings to specialized colors and finishes, manufacturers are offering tailored solutions that match the exact requirements of different applications.

For example, food-grade PVC hoses must comply with strict health regulations, ensuring they are non-toxic, odorless, and resistant to oils and fats. On the other hand, hoses used in chemical processing must be chemically inert, capable of handling corrosive fluids without degrading.

Customization also extends to aesthetic and functional features. For industries where branding or color coding is essential, manufacturers offer hoses in various colors, helping businesses differentiate hoses based on their function or content, thus improving safety and efficiency.

6. Eco-Friendly Manufacturing and Recycling

With growing environmental concerns, the demand for sustainable manufacturing practices is rising across all industries, and PVC hose manufacturing is no exception. Leading manufacturers are adopting eco-friendly production methods, which include reducing emissions, using energy-efficient machinery, and sourcing raw materials responsibly.

One notable innovation is the development of recyclable PVC hoses. Manufacturers are now designing hoses that can be easily recycled at the end of their lifecycle, reducing waste and contributing to a circular economy. Some companies are even producing hoses made from recycled PVC, offering a greener alternative without sacrificing quality or durability.

7. Smart Hoses with Sensor Integration

The future of PVC hose innovation may well lie in the integration of smart technology. While still in the early stages of development, smart hoses equipped with embedded sensors have the potential to revolutionize industries by providing real-time monitoring of pressure, temperature, and flow rates.

These smart hoses could alert operators to potential issues, such as blockages or leaks, before they become critical, thereby preventing costly downtime or equipment damage. In industries like chemical processing or oil and gas, where safety is paramount, the ability to monitor hose performance in real-time could offer significant operational and safety benefits.

Conclusion: Innovating to Meet the Future

As industries evolve, the demands placed on PVC hoses continue to grow. From advanced materials and reinforcement technologies to antimicrobial properties and smart solutions, manufacturers are rising to the challenge by creating hoses that meet the specific needs of modern applications. Whether it’s enhancing durability, improving safety, or offering more sustainable options, these innovations ensure that PVC hoses will remain at the forefront of industrial processes for years to come.

Through continual investment in research and development, manufacturers are not only addressing today’s challenges but also laying the groundwork for the next generation of industrial hoses. This commitment to innovation positions PVC HOSE Manufacturer as key players in the future of industry, where reliability, flexibility, and sustainability are critical to success.